Page 31 - European Energy Innovation - autumn 2017 publication

P. 31

Autumn 2017 European Energy Innovation 31

ELECTROMOBILITY

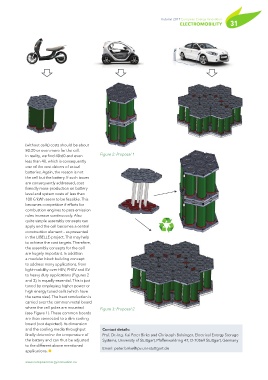

(without cells) costs should be about Figure 2: Proposal 1

80:20 or even more for the cell.

In reality, we find 40:60 and even Figure 3: Proposal 2

less than 40, which is consequently Contact details:

one of the cost drivers of actual Prof. Dr.-Ing. Kai Peter Birke and Christoph Bolsinger, Electrical Energy Storage

batteries. Again, the reason is not Systems, University of Stuttgart, Pfaffenwaldring 47, D-70569 Stuttgart, Germany

the cell but the battery. If such issues Email: peter.birke@ipv.uni-stuttgart.de

are consequently addressed, cost

friendly mass-production on battery

level and system costs of less than

100 €/kWh seem to be feasible. This

becomes competitive if efforts for

combustion engines to pass emission

rules increase continuously. Also

quite simple assembly concepts can

apply and the cell becomes a central

construction element – as presented

in the LIBELLE-project. This may help

to achieve the cost targets. Therefore,

the assembly concepts for the cell

are hugely important. In addition

a modular block building concept

to address many applications, from

light-mobility over HEV, PHEV and EV

to heavy duty applications (Figures 2

and 3), is equally essential. This is just

tuned by employing higher power or

high energy tuned cells (which have

the same size). The heat conduction is

carried over the common metal board

where the cell poles are mounted

(see Figure 1). These common boards

are then connected to a slim cooling

board (not depicted). Its dimension

and the cooling media throughput

finally determine the temperature of

the battery and can thus be adjusted

to the different above mentioned

applications. ●

www.europeanenergyinnovation.eu