Page 60 - European Energy Innovation - summer 2019 publication

P. 60

60 Summer 2019 European Energy Innovation

DECARBONISING HEAVY INDUSTRY

All the way to net-zero:

decarbonising heavy industry

in Europe is feasible

By Rannveig van Iterson, Simon Wolf, European Climate Foundation

After many years of slow progress, solutions for deep decarbonization of heavy industry become

visible and stakeholders develop an EU industry climate strategy to get there

Heavy industry has been

the stepchild of European sector is covered by the European cement and other energy and e

climate debates and policy Emissions Trading System (ETS), but mission intensive industries was

making for many years. The a vision for deep decarbonization widely missing until very recently. The

of the European steel, chemicals, reason for this is that these sectors

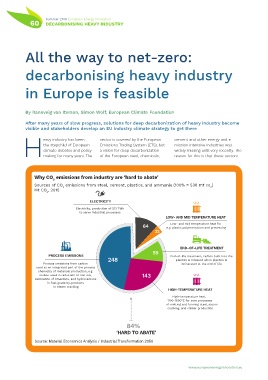

Why CO2 emissions from industry are ‘hard to abate’

Sources 2o0f1C5O2 emissions from steel, cement, plastics, and ammonia (100% = 536 mt co2)

Mt CO2,

ELECTRICITY

Electricity, production of 213 TWh

to serve industrial processes

LOW- AND MID TEMPERATURE HEAT

64 Low- and mid temperature heat for

e.g. plastic polymerisation and processing

22

PROCESS EMISSIONS 248 59 END-OF-LIFE TREATMENT

Process emissions from carbon 143 End-of-life treatment, carbon built into the

used as an integrated part of the process plastics is released when plastics is

incinerated at the end of life

chemistry of materials production, e.g.

carbon used in reduction of iron ore, HIGH-TEMPERATURE HEAT

calcination of limestone, and hydrocarbons

High-temperature heat,

in fuel-grade by-products 1100-1600°C for core processes

in steam cracking of melting and forming steel, steam

cracking, and clinker production

84%

‘HARD TO ABATE’

Source: Material Economics Analysis / Industrial Transformation 2050

www.europeanenergyinnovation.eu