Glycerol – an abundant by-product of biodiesel plants – as well as other bio-based feedstocks, can be converted into valuable liquid fuels and reduce the carbon dioxide emissions in aviation and shipping sectors up to 70%.

The project GLAMOUR - GLycerol to Aviation and Marine prOducts with sUstainable Recycling, funded in the frame of the European Union’s Horizon 2020 research and innovation programme under grant agreement N° 884197, plans to implement two new processes which could produce synthetic paraffin kerosene and marine diesel oil with an energy efficiency of 65% starting from biowaste materials. The initiative is focusing on a combination of high pressure, auto-thermal reforming/gasification using chemical looping to produce syngas and the integration of Fischer-Tropsch compact reactor integrated with 3D printed structured catalyst. The GLAMOUR process will achieve a full conversion of the crude glycerol into synthetic paraffine kerosene (FT-SPK) to be used as jetfuel and into marine diesel oil (MDO) with an energy efficiency of 65%. These improvements will increase the overall revenue of existing 2nd generation bio-diesel plants reducing the cost for large scale biomass-to-liquid production processes up to 35% and the CO2 emissions up to 70%. At the end of the project, the GLAMOUR technology will reach a TRL 5 level of innovation in the field of material science, process engineering, sustainability and socio-economic studies.

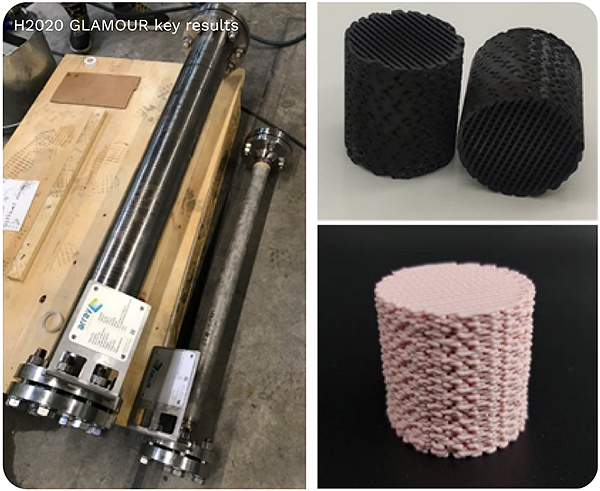

The GLAMOUR consortium, composed by 10 partners from six different EU countries led by the University of Manchester, has already achieved some interesting results from the beginning of the project. A comprehensive campaign has been conducted to optimize the crude glycerol purification by combining physiochemical processes and advanced analytical data processing methods. Current testing includes electric-driven process to further reduce the impurities. In terms of glycerol gasification, new material formulation based on nickel and iron are being tested by project partner to achieve >95% glycerol conversion and a tailored composition; testing of this material is currently ongoing coupled with process modelling to optimize the formulation and process operation. Syngas to kerosene and liquid product has been tested on different conventional and 3D printed samples showing promising results in terms of conversion and yield. A comprehensive benchmark of the process performance has been carried for about three months with three different catalysts and against commercial micro-structured reactor performance (provided by INERATEC). Full design of GLAMOUR prototype at a TRL5 demonstration has been completed and the equipment required for scale-up the process has been designed and most of the items were ordered for the final TRL5 demonstration that will start later in 2022 in the Netherlands. The conceptual design at industrial scale simulation is confirming the expected Key performance indicators also in terms of life cycle assessment demonstrating the validity of the process and relevance at industrial scale.

Project Contacts

Vincenzo Spallina, Project Coordinator

Email: vincenzo.spallina@manchester.ac.uk

www.glamour-project.eu

This project has received funding from the European Union's Horizon 2020 research and innovation programme under grant agreement No 884197.