Within the context of sustainability

and the global efforts for CO2

emission reduction, the investigation

of routes for biomass conversion

to fuels and chemicals has

received tremendous attention.

The

production of bio-based building

blocks and the associated production

of bio-polymers could make a big

impact in improving the sustainability

of the chemical and petro-chemical

industry. It also offers a promising

opportunity to improve the overall

economics and sustainability of the

bio-based industry. EU has declared

the bio-based products sector to be

a priority area with high potential for

future growth, reindustrialization, and

addressing societal challenges.

BioCatPolymers is a 3-year European

project funded by the European

Union's Horizon 2020 research

and innovation programme under

grant agreement No 760802.

The BioCatPolymers consortium

comprises seven partners from

five countries CERTH (Greece), BPF

(Netherlands), PDC (Netherlands),

Quantis (Switzerland), Covestro

(Germany), Sekab (Sweden) and

Visolis (Netherlands). The project is

coordinated by CERTH, the Centre

for Research & Technology Hellas

(Greece).

The main objective of BioCatPolymers

is to demonstrate a cost-effective,

sustainable and effi cient cascade

technological route for the conversion

of low-value, low-quality residual

biomass to bio-polymers with equal

or better performance than their

fossil-based counterparts. The project

targets specifi cally the efficient

and economic production of two

monomers with very large markets,

isoprene and 3 methyl pentanediol

(3MPD).

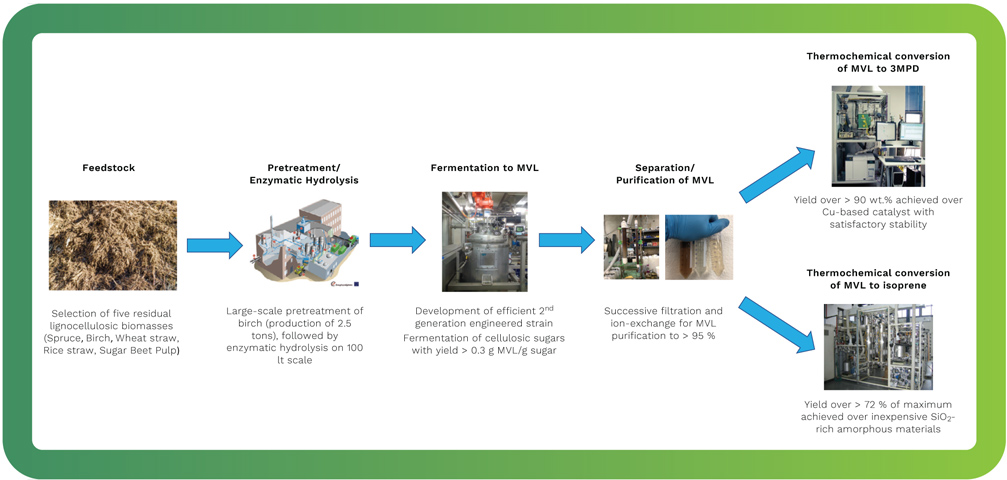

The novel approach proposed

in BioCatPolymers surpasses

the impediments of traditional

solely bio-based approaches. The

BioCatPolymers process starts

from the optimized pretreatment of

lignocellulosic biomass, combined

with efficient enzymatic hydrolysis to

sugars. Using innovative engineered

strains, sugars are fermented with

high yield to mevalonolactone (MVL).

After separation and purification

from the fermentation broth, MVL

is converted, via highly efficient and

selective thermochemical catalytic

processes, to the monomers, which

are fi nally purified to polymer grade

quality. These monomers can be

further processed for the production

of synthetic rubber, polyurethanes

and polyesters that can be used in

a wide range of every day products,

such as car tires, synthetic shoe

material, life jackets and foams for

insulation.

The project is currently entering

its third year. The first two years

have been very successful and the

project partners have achieved to

develop efficient strains, catalysts

and processes for all steps in the

BioCatPolymers value chain on

small scale. Currently, the scaleup

activities are on-going to

demonstrate the integrated process

on a 0.5 ton biomass/day scale. The

main highlights of the work that has

been performed so far are shown in

the figure below.

Contact information:

Website: www.biocatpolymers.eu

Email: biocatpolymers@cperi.certh.gr