To promote the technical

feasibility of Algae Biofuels,

the EU FP7 Energy

programme launched in 2011

three projects on a demonstration

scale. All-Gas is the only one of this

cluster to produce algae and operate

the entire value chain of biofuel

conversion and fl eet demonstration.

The integrated design of energy

efficient wastewater treatment, based

on high-rate algal ponds, allows to

harvest nutrients, while producing

biogas and reuse water without

external energy input.

Full sustainability is reached based on

a circular economy concept, avoiding

dependency on fresh water, arable

land and inorganic fertilizers. The Life

Cycle Assessment (LCA) performed

on the demonstration plant showed

an energy return on investment

(EROI) of 4, changing the paradigm

of effluent treatment from energy

consumer to net energy exporter.

The consortium www.all-gas.eu, led by

Aqualia, demonstrated on large scale

the sustainable production of biofuels

based on low-cost microalgae

cultures. 2 ha of raceway ponds

and related flotation harvesting and

thickening were operated over several

years, with the biomass digested to

biogas and upgraded to biomethane,

which fueled 3 test vehicles that ran

for 70,000km each over two years.

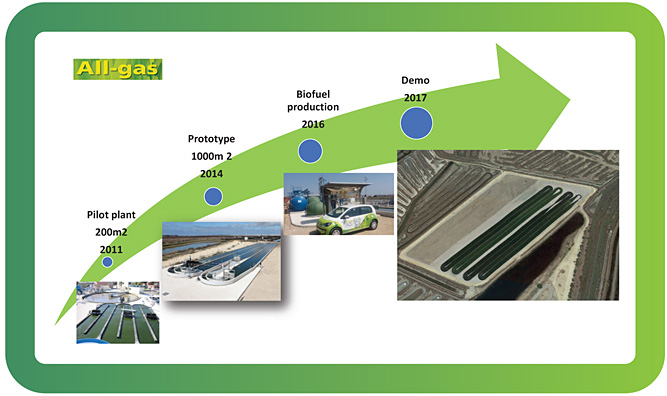

Previous to the implementation of

the Demo phase in 2017, a stepwise

scale up of the process was carefully

designed and implemented in order

to minimize risk. Pilot plants were

installed in 2011. In 2014 the plant

was scaled up to a 1,000m2 prototype

and its respective work and testing

program allowed to confirm key

parameters. A biomass productivity

with a yearly average above 100t/ha

was achieved, and biomethane

yield reached 200L CH4/kg VS. In

May 2016 a first car validated the

microalgae fuel quality produced in

All-Gas project.

The biogas upgrading unit fueled a

test fleet of 3 dedicated vehicles,

as well as 4 other vehicles for

municipal services. To evaluate the

effect of the biomethane on engines,

each test car was monitored over a

70,000km evaluation program. Over

the duration of the project, All-Gas

was able to move the fleet vehicles in

Chiclana around 400,000km, which is

equivalent to travel around the world

10 times.

The demo operation showed that

each hectare of algae culture has

a wastewater treatment capacity

around 1,000m3/d, producing

biomethane above 1,300kg CH4yr

– enough to fuel 20 cars (at

4,5kg/100km and 15,000 km/yr).

This represents four times more than

what is achieved with conventional

biofuels, such as bioethanol from

sugarcane or biodiesel from palm oil,

both yielding about 5,000L/ha/yr.

Additionally to renewable energy

production, the circular economy

concept of the all-gas project

signifi cantly reduces the electricity

required to treat wastewater.

Compared to conventional processes,

for each 1,000m3/d treated around

0.4kwhm3 can be saved - equivalent

to the yearly electricity consumption

of more than 20 people. Extraction

of lipids was also demonstrated with

BDI's RepCat process, producing a

few liters of algae-biodiesel within

the specifi cation of EN 14214 except

for the sulphur content. Some of

the results are included in the new

documentary Brave Blue World.

Brave Blue World trailer