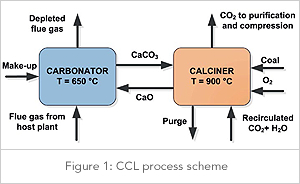

Calcium Carbonate Looping (CCL) is a highly

efficient post-combustion CO2 capture

technology utilizing limestone based sorbents

(see Fig.1). CCL is particularly suited for

retrofitting power plants as well as industrial plants (cement,

steel, etc.). For power plant applications, CCL combines

low net efficiency penalties of 5-7 %-points (incl. CO2

compression) with low CO2 avoidance costs below

30 €/tCO2. The feasibility of CCL has been proven by various

pilot plants.

Calcium Carbonate Looping (CCL) is a highly

efficient post-combustion CO2 capture

technology utilizing limestone based sorbents

(see Fig.1). CCL is particularly suited for

retrofitting power plants as well as industrial plants (cement,

steel, etc.). For power plant applications, CCL combines

low net efficiency penalties of 5-7 %-points (incl. CO2

compression) with low CO2 avoidance costs below

30 €/tCO2. The feasibility of CCL has been proven by various

pilot plants.

The SCARLET project aims to bring CCL to the next level

of maturity by obtaining reliable information and tools for

scale-up of the technology, including the following activities:

- Pilot testing at 1 MWth scale

- Development of scale-up tools

- Engineering for a 20 MWth pilot plant

- Techno-economic/environmental assessment for power,cement, steel sector

A highly qualified consortium consisting of academic partners

(Technische Universität Darmstadt, University of Ulster, CERTH),

technology providers (GE Carbon Capture, Steinmüller

Babcock Environment, Lhoist, SWR Engineering) and end users

(Uniper, RWE, ArcelorMittal, CEMEX) provides the expertise

that is required for successful scale-up of the CCL technology.

Four long-term pilot tests (4 weeks each, 24/7) have been

performed at the 1 MWth pilot plant at TU Darmstadt (see

Fig. 2). CO2 was continuously captured for more than 1,200

hours from coal originated flue gas under a wide range of

conditions. Overall CO2 capture efficiencies up to 97% were

achieved proving the high potential of the process.

Four long-term pilot tests (4 weeks each, 24/7) have been

performed at the 1 MWth pilot plant at TU Darmstadt (see

Fig. 2). CO2 was continuously captured for more than 1,200

hours from coal originated flue gas under a wide range of

conditions. Overall CO2 capture efficiencies up to 97% were

achieved proving the high potential of the process.

Scale-up tools have been developed and validated against

experimental data of the pilot tests. These include a steadystate

process model for heat and mass balance, a dynamic

process model for flexibility evaluation as well as various

Computational Fluid Dynamics (CFD) approaches for 3D

reactor simulation of fluidized bed reactors.

A 20 MWth pilot plant will most probably be next step

towards full-scale demonstration of CCL technology. The

basic design and engineering of such a pilot plant are

carried out considering UNIPER’s Emile Huchet (France)

hard coal power plant as the host site. Health and safety

analysis as well as technical risk assessment are conducted

for this pilot plant.

The full-scale integration of CCL into various power

(hard coal, lignite) and industrial (cement, steel) plants is

assessed for selected host sites of the industrial partners.

Heat and mass balances for various retrofit scenarios are

established to determine the energy requirements as well

as CO2 avoidance costs. The environmental impact of the

technology is assessed by life cycle analysis (LCA).

Save the Date! – The 2nd Public Workshop will take place

on 23rd March 2017 at Technische Universität Darmstadt

presenting the final results of the SCARLET project. There

will be the possibility to visit the CCL pilot plant. The

workshop will be free of charge. Registration can be made

via email.

This project is funded by the European Union's 7th Framework Programme under grant agreement no. 608578.

Contact details:

www.project-scarlet.eu

Email: info@project-scarlet.eu