Page 9 - European Energy Innovation - Winter 2014

P. 9

Winter 2014 European Energy Innovation 9

COMMUNICATION

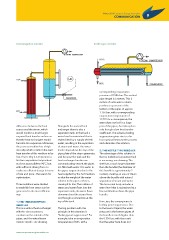

Thermosyphon reboiler Kettle type reboiler

difference between the heat Alongside the vertical heat corresponding evaporation

source and the steam, which exchanger there is also a pressure of 0.556 bar. The vertical

would result in a much larger separation tank. In that tank a pipe length is 6 metres. This 6

required heat transfer surface so water level is maintained that is metres of extra water column

that the heat exchangers would replenished by a supply of fresh produces a pressure at the

become too expensive. Moreover, water, resulting in the separation bottom of the pipes of approx.

the process medium has a high of steam and water. The water 1.156 bar, with a corresponding

viscosity, which results in the wall level is kept above the top of the evaporation temperature of

heat transfer of this medium to be pipe plate of the steam generator, 113˚C! As a consequence, the

low. That is why it is important to and because the tank and the water does not boil in a large

find an evaporation temperature heat exchanger function as part of the pipes, but takes place

as close as possible to 90˚C, but communicating vessels the pipes only though a low heat transfer

with sufficient driving force to are filled with water. The water in coefficient. This adverse boiling

realise an efficient design in terms the pipes evaporates due to the suppression gives rise to a far

of size and price - the search for heat supplied by the hot medium, from optimal heat transfer process

optimisation. so that the weight of the water and eliminates this solution.

column in the pipes reduces,

Three solutions were studied causing it to rise. The mixture of 2: THE KETTLE TYPE REBOILER

to establish how steam can be steam and water flows into the The advantage of this solution is

generated in the most efficient separation tank, the water flows that no individual separation tank

way. downward and the steam flows is necessary; see drawing. The

out through a connection at the shell has a much larger diameter

1: THE THERMOSYPHON top of the tank. than the bundle (the diameter of

REBOILER this bundle is approximately 2

This is a vertical heat exchanger The big problem with this metres), creating an area of steam

with the viscous process principle in this situation is above the bundle with natural

medium on the outside of the “boiling point suppression”. For separation of steam and water.

pipes, and the water/steam example, take an evaporation The horizontal body includes a

mixture inside ; see drawing. temperature of 84˚C with a water level that is maintained at a

few centimetres above the pipe

bundle.

Here, too, the consequence is

boiling point suppression. Due

to the level of liquid, the water

pressure in the bottom pipes of

the bundle is much higher than

the 0.556 bar, with the result

that the water here does not

www.europeanenergyinnovation.eu

COMMUNICATION

Thermosyphon reboiler Kettle type reboiler

difference between the heat Alongside the vertical heat corresponding evaporation

source and the steam, which exchanger there is also a pressure of 0.556 bar. The vertical

would result in a much larger separation tank. In that tank a pipe length is 6 metres. This 6

required heat transfer surface so water level is maintained that is metres of extra water column

that the heat exchangers would replenished by a supply of fresh produces a pressure at the

become too expensive. Moreover, water, resulting in the separation bottom of the pipes of approx.

the process medium has a high of steam and water. The water 1.156 bar, with a corresponding

viscosity, which results in the wall level is kept above the top of the evaporation temperature of

heat transfer of this medium to be pipe plate of the steam generator, 113˚C! As a consequence, the

low. That is why it is important to and because the tank and the water does not boil in a large

find an evaporation temperature heat exchanger function as part of the pipes, but takes place

as close as possible to 90˚C, but communicating vessels the pipes only though a low heat transfer

with sufficient driving force to are filled with water. The water in coefficient. This adverse boiling

realise an efficient design in terms the pipes evaporates due to the suppression gives rise to a far

of size and price - the search for heat supplied by the hot medium, from optimal heat transfer process

optimisation. so that the weight of the water and eliminates this solution.

column in the pipes reduces,

Three solutions were studied causing it to rise. The mixture of 2: THE KETTLE TYPE REBOILER

to establish how steam can be steam and water flows into the The advantage of this solution is

generated in the most efficient separation tank, the water flows that no individual separation tank

way. downward and the steam flows is necessary; see drawing. The

out through a connection at the shell has a much larger diameter

1: THE THERMOSYPHON top of the tank. than the bundle (the diameter of

REBOILER this bundle is approximately 2

This is a vertical heat exchanger The big problem with this metres), creating an area of steam

with the viscous process principle in this situation is above the bundle with natural

medium on the outside of the “boiling point suppression”. For separation of steam and water.

pipes, and the water/steam example, take an evaporation The horizontal body includes a

mixture inside ; see drawing. temperature of 84˚C with a water level that is maintained at a

few centimetres above the pipe

bundle.

Here, too, the consequence is

boiling point suppression. Due

to the level of liquid, the water

pressure in the bottom pipes of

the bundle is much higher than

the 0.556 bar, with the result

that the water here does not

www.europeanenergyinnovation.eu