The MariGreen project is focused on the development of innovations for greener and low-emission shipping that will ultimately reduce the ecological footprint of the shipping industry. This collaborative project between Germany and the Netherlands brings together shared goals to push international standards of excellence even further whilst promoting the profile of the region as a model in Green Shipping. Through a consortium of fifty-nine German and Dutch maritime companies and research institutions, a total of twelve innovation projects will be realized as part of the broader MariGreen Project.

LNG offers a low-emission and environmentally friendly alternative to conventional fuels in shipping. However, climate-relevant emissions can occur in the LNG chain from the terminal to combustion in the engine. In particular, the escape of methane (the main component of LNG) plays a special role This phenomenon is known as ‘methane slip’ Engine manufacturers are continuously developing design upgrades to reduce methane slip. Today limits below 4gr/ kWh, are achieved. However considering the global need to reduce CO2 emissions ("Paris Climate Agreements"), further reduction is desired. To this end, one MariGreen sub-project is dedicated to developing and testing a viable market-ready solution for marine gas engines to eliminate methane slip.

Euro Stage V includes methane emissions under hydrocarbon emissions (HC). These HC-limits for gas engines remain quite lenient compared to diesel engines (0.19 g/kWh for diesel engines vs. 1.10 g/kWh for gas engine (56kW≤P≤560kW) and 6.00 g/kWh for gas engines with P>560kW). Nevertheless, methane emission abatement techniques for lean-burn gas engines will gain more ground as LNG market uptake continues.

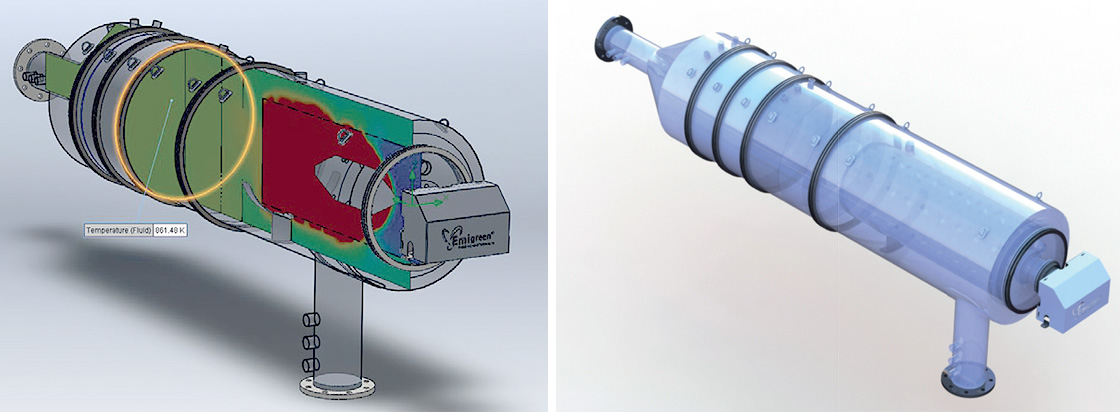

The catalyst being developed and tested in the project MariGreen will have the task of converting the residual methane in the exhaust gas into carbon dioxide and water, thus resulting in a significantly cleaner engine system. The design and development of the catalyst is in its final stages, with three of the most promising catalyst formulations ready for testing. Meanwhile, a design sketch for the prototype is being finalized together with a list of components that will be required for construction (see images below). After all the components have been delivered, construction of the prototype is currently being carried out by Emigreen B.V., Wärtsilä B.V., Koedood Diesel Service and the Emden-Leer University of Applied Sciences.

Like most catalyst with oxidative capacity, methane oxidation catalysts (MOC) are based on rare earth metals. Beside these elements the MOCs under consideration consist of a more exotic cocktail of elements. An impregnation process is used to bind the powdered carrier material to the base metal substrate. This carrier is calcinated at elevated temperatures for several hours, nitrates solutions are used to subsequently impregnate the carrier. Later drying and calcination is done to finish the catalyst.

A suitable testing facility for the catalyst has recently been found at Intertech B.V. Located in Groot-Ammers. They offer the required expertise and testing space equipped with a cooling system, exhaust and gas control systems in place to carry out controlled tests with valid outcomes. Testing is planned to begin in April 2018.

The MariGreen project (www.marigreen.eu) is supported in the framework of the Interreg V-A program Deutschland-Nederland with funds from the European Regional Development Fund (ERDF) and national co-financing from Germany and the Netherlands. The MariGreen project is coordinated by lead partner MARIKO GmbH in Leer, together with Co-Partner FME, the entrepreneurial organization for the technology industry.

Contact Details:

MARIKO GmbH

Bergmannstraße 36

26789 Leer

Tel: 0491 926-1175

Fax: 0491 926-1171

email: sascha.strasser@mariko-leer.de

web: www.mariko-leer.de